Do not replace your dryer machine. Install a dryer vent correctly

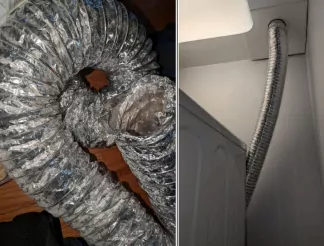

The dryer’s air vent allows moist air to escape to the outside. If the vent is clogged, the lint in the dryer can ignite. And we see it all the time in the news. However, a burnt-out dryer hose and an explosion of a dryer isn’t the worst-case scenario. Worse, if the dryer is installed incorrectly – the transition hose goes into the wall – the fire can start there. Then it will be difficult to extinguish it because there will be no access to the behind-the-wall area.

The fire can easily travel around the house/building or spread to neighboring buildings. In addition, improper installation can lead to the misplacement of important ventilation components, and damaged areas will quickly become a breeding ground for mold. Unfortunately, improper installation of dryer vent ducts is very common. Whether you need a new dryer vent hose or you want to replace an old or unsafe one, our services are tailored to your home’s individual needs.

By conducting a preliminary inspection and evaluation, we select and offer customized ventilation solutions that are ideal for your installation.

Free ConsultationPotential Risks You May Face Without Proper Dryer Duct Installation

If your dryer vents are damaged, improperly installed, or made of the wrong materials, you may face the following risks:

- Lint build-up inside the dryer

- Increased energy costs

- Reduced life cycle and overall efficiency of your dryer

- Carbon monoxide leakage from the dryer

- Fire hazard

- Mold growth

- Unnecessary costs for repairs or replacements that won't work.

We Follow the Code for Installing a Dryer Vent System

We put your safety first. That is why we are primarily guided by the International Residential Code (IRC M1502) which regulates the connection type, and lengths for the dryer vent, and is a guide for the Installation or Replacement of the Vent.

For proper operation of the dryer and protection against fire, correct installation of the vent is necessary. If technicians follow the code during installation, there is no such case as a fire situation. This is what always guides our work:

"Transition ducts shall not be concealed within construction. Flexible transition ducts used to connect the dryer to the exhaust duct system shall be limited to single lengths not to exceed 8 feet (2438 mm), and shall be listed and labeled in accordance with UL 2158A."

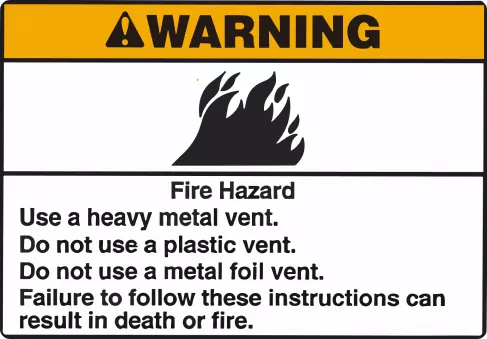

Pay Attention

It clearly states that you should use heavy metal vents and DO NOT USE PLASTIC OR THIN FOIL DUCTS. The reason is that plastic or foil duct feeds the fire, vinyl melts and spreads the fire.

As reported by the National Fire Protection Association (NFPA) in 2022, dryers and washers cause an average of 15,970 fires each year, with dryers causing 92% of them and an average of $200 million in property damage.

Get A Quote Now

We Will Provide You A Quote Over Your Phone Number & Email

Leave The Dryer Vent Hose Installation To The Professionals

Installing a dryer duct system may seem like a simple task#, but it must be done correctly to prevent any costly problems in the future. It often happens that homeowners try to solve the problem on their own. As a result, the situation can only get worse.

As we understand how dryer systems work, we know how to make sure they work at their best. Based on the regulations of CODE M1502, we check the current condition of the vent and clean the dryer heating element, the transition hose, and the vent. During the inspection, we may find:

- the dryer vent is clogged

- the lint filter is filled with lint

- the transition hose enters the wall, and usually it’s a vent line that should be installed and accessible

- the vent is connected to the dryer via a transition hose, that doesn’t fit the requirement and creates a fire hazard situation.

At Green Ductors, our team of highly experienced professionals is well-versed in all aspects of dryer vent installation. Our experts provide guidance on the best routing and use of high-quality materials that adhere to recommended standards, ensuring optimal performance for your dryer ductwork.

Once the transition hose is quality installed, we guarantee the safe and efficient operation of your dryer. There is no need to spend unnecessary money on repairing or replacing your dryer.

Invest in reliable dryer hose installation services!

Choose Green Ductors For Dryer Vent Install

At our company, we take pride in our commitment to excellence. When you choose us for HVAC dryer vent installation, you benefit from:

Experienced Technicians:

Our licensed experts have years of experience in dryer vent installation.

Quality Materials:

We use high-quality materials that stand the test of time.

Top-notch service:

We provide high-end installation and top-notch results according to your unique needs.

Safety:

Your safety is our priority. We follow all safety standards and building codes.

Satisfaction Guarantee:

We do our best for you to stay satisfied and mind-free from our service.

Trusted Partners:

We are NADCA, BPI and Chimney Professionals certified.

Frequently Asked Questions

At Green Ductors, we are committed to ensuring that you are aware of all issues related to dryer vents. Your knowledge is your safety. We invite you to familiarize yourself with the most frequently asked questions about dryer vent installation. Team and we will be happy to advise you.

Do you have to hook up the dryer vent?

Yes. A dryer vent is responsible for directing the humid and warm air, as well as any potentially harmful byproducts of combustion, produced by your dryer outside of your home.

How far can you run a dryer vent pipe?

According to IRC M1502.6 “Length of duct", the maximum developed length of a clothes dryer exhaust duct shall not exceed 35 feet from the dryer location to the wall or roof termination.

How long does the installation process take?

Depending on the individual characteristics of your home and other factors, the process can take up to 8 hours.

Do I need to be present during installation?

It's not necessary, but you're welcome to be there if you prefer.

How often should I have my dryer vent inspected?

We recommend regular inspections to ensure safety.

Is professional installation really necessary?

Yes, professional installing of a dryer vent hose is crucial for your safety and the dryer’s efficiency. DIY installations can lead to many problems.

Could not find the answer to your question?

Please contact our expert team and we will be happy to advise you.

Find Industry-Leading Duct Cleaning Service Near You

In NY and NJ areas, we are a highly qualified air duct&dryer vent cleaning company with a proven track record. Thanks to our customer-centered approach and commitment to excellence, we have many happy homeowners and business owners to our credit. We are trusted. We are chosen.

Want to know more about our services or need expert consultation? Just fill out the form below and one of our experienced team members will get back to you promptly.

At Green Ductors we proudly serve our clients in NY&NJ areas.